Seasonal Spotlight: Powering Peak Performance for Summer Adventures with Custom Bending Solutions

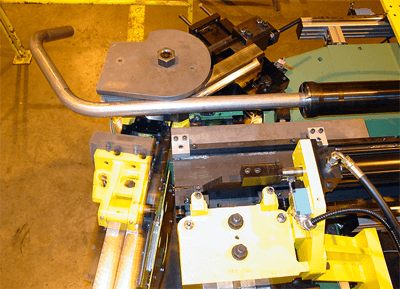

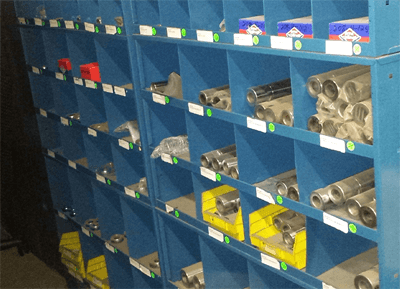

As temperatures rise and summer adventures hit full stride, manufacturers of recreational vehicles (RVs) and all-terrain vehicles (ATVs) shift into hi...