Bend Tooling

- Home

- Tooling

A Leader in Bend Tooling Design & Manufacturing

For over 60 years, H&H Tooling, a Pines Engineering brand, has set the benchmark for quality and innovation in bend tooling. H&H is a pioneer in the industry, delivering precision tooling that ensures lasting performance. From custom solutions to stock tooling, we are equipped to meet all your bending needs.

- We design and manufacture tooling for ALL rotary and compression bending machines (not just Pines equipment).

- We specialize in custom tooling designed for your application for your convenience.

- We stock some items for your convenience.

Your Single Source for Tube and Pipe Bending Tooling and Equipment

When you purchase a Pines bender, we design and manufacture your tooling, serving as a single source for all your bending needs.

We have access to all the historical records of every Pines bender ever made, allowing our tooling engineers to easily gather technical details about your unique equipment if needed.

Additionally, we produce tooling for all bending machines — not just Pines benders.

In Stock for Your Convenience

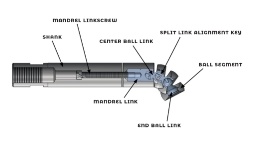

Whether you need tooling for a new machine or support for existing equipment, Pines Engineering and H&H Tooling are your single source for all bending needs. To minimize downtime, we stock a variety of common mandrels, linkage components, and springs, including:

- Linkage: Shank Link, Center Ball Link, End Link

- Ball Segment

- Socket Headed Cap Screw

- Detent Balls and Springs

- Shank

You never have to worry about their tools wearing out.

H&H Tooling shares many of the same brand characteristics as Pines. Solid quality. Consistent.

H&H Tooling Brochure

Leverage our team’s expertise and learn why we are bend tooling specialists.

The Types of H&H Tooling Explained

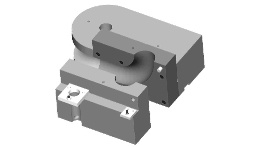

Standard Draw Bend Tooling

The bend die is the primary tool around which the tube is formed to produce a specific bend radius. The clamp die is used with the bend die to grip the tube. The pressure die functions as a containment tool during bending. The primary function of the wiper die is to prevent the tube from wrinkling during bending. The mandrel is the tooling component that provides support to the inside of the tube.

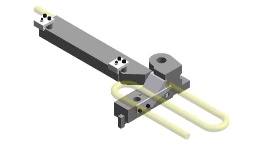

Uni-Flex Mandrels

The uni-flex mandrel has become the world standard for internal ball-style mandrels. The unique ball and socket linkage originally designed and patented by H&H Tooling, provides unmatched setup and bending characteristics.

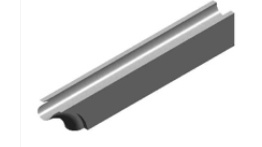

Wiper Dies & Tips

Wiper dies are available in the standard solid-style or in the replaceable tip-style.

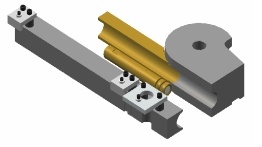

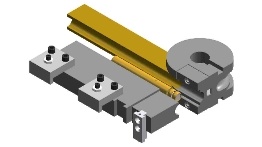

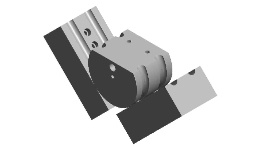

Reverse Interlocking Draw Bend Tools

Originally designed and patented by H&H Tooling in 1963, Interlock tooling is distinctive due to its self-aligning rail design.

Compound Tooling

A compound grip is a grip or clamp area with a machined tube groove matching the contour of the previous bend. These grip sections are defined as either simple or complex depending on the specific plane rotation between bends.

Serpentine Tooling

Serpentine tools are designed to exact outside diameter/centerline radii specifications requiring continuous 180° plane change bends.

Single-Finger Tooling for Square & Rectangular Parts

If the bender is not equipped with a split die actuator, single-finger tools are used to ensure the easy removal of the square or rectangular part after the bend is complete. The clamp and pressure die are designed with fingers that enclose the tube into the bend die during the bend cycle. When the tool holders open, the fingers are removed from the bend die and the part is easily unloaded.

Vertical Bender Tooling

Compression bending is the method used on bending presses and some rotary bender applications. Work is wrapped around a bending form (punch die) by a pivoting wiper shoe (wing die) as the bending form is driven downward.

Get Precise, Quality Tooling

The experienced team at H&H Tooling is here to provide the exact tooling you need. Request a quote to learn how we can create custom tooling for your equipment — whether it's from Pines or another manufacturer.