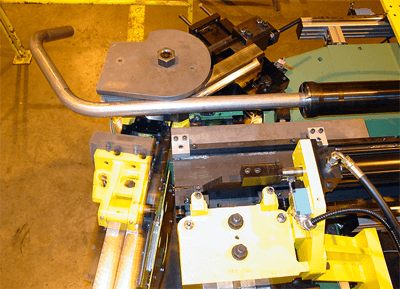

CNC 150

Pines CNC 150 Bending Machine, with capacity for 6” x .165” steel tubing, is arranged for counterclockwise rotation with 18-inch maximum centerline radius. The machine comes complete with carriage for positioning of tubes with multiple bend configurations, hydraulic mandrel extractor, heavy-duty mandrel lubricator, clamp and pressure die holders, twin overhead tie bars, automatic slide lubricator, all necessary hydraulics, valving, piping, and cylinders. Complete bender operations are self-contained in the machine base and include water-cooled heat exchanger for the hydraulic oil.