About Pines Engineering

- Home

- About

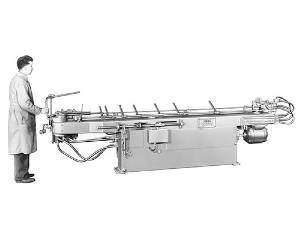

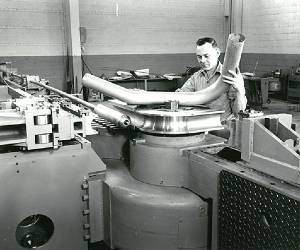

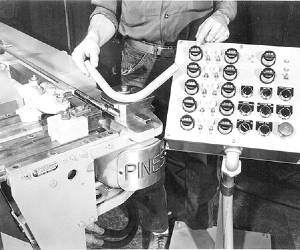

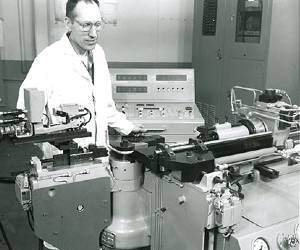

Designed to Last

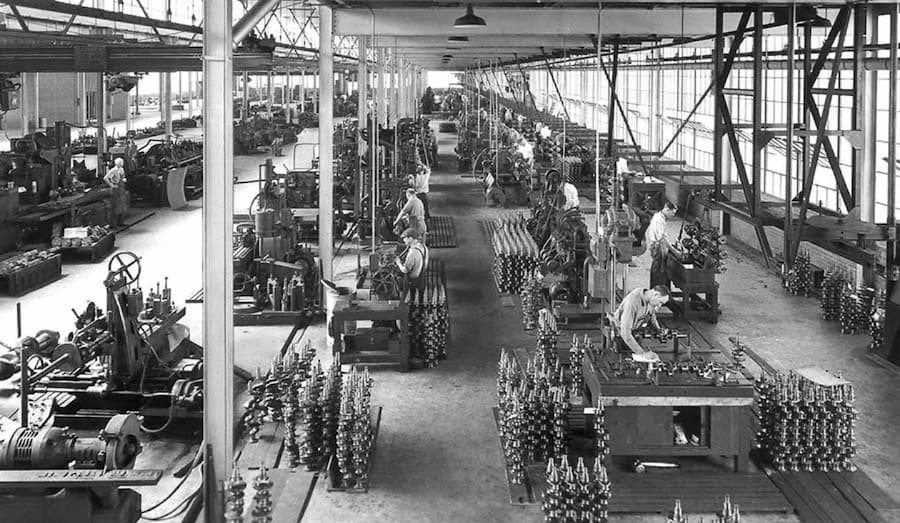

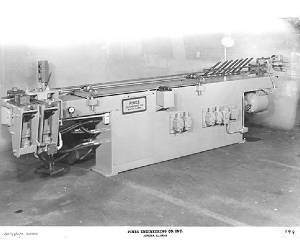

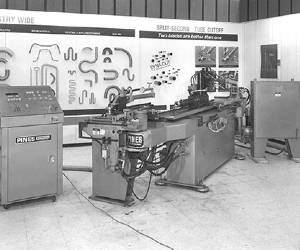

Since 1943, Pines Engineering has been the name behind the most durable and advanced tube and pipe bending technologies in the world. With ISO 9001:2015 certification and more than 75 patents, our legacy of innovation, quality, and dependability speaks for itself.

Complementing our equipment, our H&H Tooling brand designs and produces high-tolerance bend tooling for rotary and press bending machines, further solidifying our dedication to quality and performance.

We support our equipment with OEM parts and expert service, ensuring long-lasting reliability and peak performance. By offering both advanced bending machines and precision tooling through H&H Tooling, Pines Engineering provides a seamless, end-to-end solution for all your bending needs—delivering the quality and expertise that have defined us as a global leader for decades.

A ParkOhio Company

Pines Engineering is proud to be a part of ParkOhio, an industrial supply chain logistics and diversified manufacturing firm. As a member of ParkOhio, Pines Engineering benefits from being part of a globally integrated network that includes over 130 facilities across North America, South America, Europe, and Asia.

Acquired by ParkOhio in 2013, Pines Engineering is now under the umbrella of ParkOhio’s Industrial Equipment Group (IEG), alongside Ajax TOCCO Magnethermic (ATM), a key player in IEG. Pines operates within ATM's Warren, Ohio facility, which oversees all U.S. operations, providing a strong foundation for continued growth and innovation in the manufacturing sector.

With ParkOhio’s global presence and robust infrastructure, Pines Engineering is able to leverage resources, expertise, and a workforce of more than 6,400 employees worldwide, contributing to ParkOhio’s impressive annual revenue of over $1.7 billion.

In addition to our U.S. operations, Pines Engineering also maintains a strong presence in Europe through our manufacturing facility in Belgium, supporting our global reach and commitment to excellence in industrial engineering solutions.

Our History

1940

Pines was founded by the inventor of the mandrel bending machine, Byron Bower.

1941

Pines designed the first rotary bender for bicycles.

1943

Pines designed the first rotary bender for metal furniture.

1954

Pines designed the first machines that were specifically designed for bending tubing.

1955

Pines designed the first vertical compression bender.

1960

Pines produced the first Dial-A-Bend® machine control for rotary draw benders.

1962

Pines designed the first fully automatic, three-axis CNC bender.

1965

Pines patented the CNC bender carriage.

1968

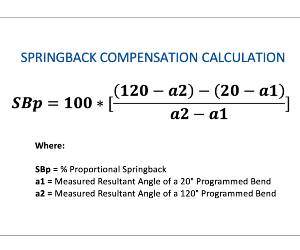

Pines introduced formulas for calculating spring-back compensation.

1969

Teledyne Corporation purchased Pines.

1976

Pines produced the first microprocessor-based controlled bender.

1985

Pines designed a bender specifically for coaxial cables in the aerospace industry.

1986

Pines designed the first NC benchtop bender for small-diameter tubes.

1994

Pines relocated from Chicago, Illinois, to Cleveland, Ohio.

1995

Pines introduced the first 40mm machine with servo-electric bend motion.

1997

Pines introduced the first pressure die booster system for the boiler tube industry and the TS2000 Windows-based CNC bender control.

1999

Pines introduced the first PLC-based control as the latest generation of digital Dial-A-Bend® controls, along with the CNC100 bender, the fastest 4” bender on the market.

2007

Pines designed the MV-2200 series bender, a custom three-axis DAB machine for the USMC.

2011

Pines introduced the CNC250, a heavy-duty 10” pipe bender — the largest CNC bender for the boiler industry.

2013

Ajax TOCCO Magnethermic, a ParkOhio subsidiary, purchased Pines.

2017

Pines introduced the Dial-A-Bend® 7 control for one- and two-axis NC machines.

2019

Pines designed the CNC e40, an all-electric bender capable of bending 40mm stainless steel tube.

2024

Pines includes electric arms on NC benders for enhanced controls, programmable pressure setting, and quick-change tooling.

Pines Engineering has been producing durable bending equipment for 80+ years.

We boast more than 75 patents throughout our history.

Industries Served

From job shops to OEMs, privately held firms to the military, our equipment helps manufacturers across many industries all over the world bend the pipes and tubes that make their products work. We specialize in the following markets:

Speak to Our Experienced Team

Contact us today for more information about customization options, pricing, or details about purchasing a Pines machine, tooling, parts, or services.